Picture this: you’re in the midst of a project requiring utmost precision, and—bam!—you realize your pressure sensor just isn’t cutting it. Statistics show that many industries experience project delays due to improper sensor readings. That’s where the oem pressure sensor comes into play. It’s not just another component; it’s a game changer in achieving accuracy across various applications.

Flaws in Traditional Solutions

Remember when pressure sensors relied on outdated technologies? Many simply couldn’t handle the parameters demanded by modern applications. Their sluggish responses often led to incorrect readings and wasted resources. When you think about it, how many failures could have been avoided? The imperfections of these older models are painfully obvious, often costing both time and money.

Principles of New Technology

This is where the tide begins to turn. New-generation oem pressure sensors leverage advanced algorithms and edge computing methodologies. They comprise materials that enhance biocompatibility for medical applications and ensure reliability in industrial settings. Just think about it—what if every data point was as accurate as it could be? You’d be one step closer to seamless performance!

User Benefits in Numbers

Quantified results shine bright here. Users who’ve switched to modern pressure sensors report up to a 30% increase in efficiency. Imagine cutting your costs and improving integration with other smart technologies in your ecosystem—what a win! The evolution in this space is tangible and undeniable, and frankly, it’s thrilling to watch.

Evaluating Your Choices

So, what should you look for when selecting a pressure sensor? Always verify these 3 metrics when choosing solutions: ① Accuracy ② Response Time ③ Compatibility with your existing systems. Keeping these in mind will empower you to make informed decisions in this technical arena.

Understanding OEM Pressure Transducers

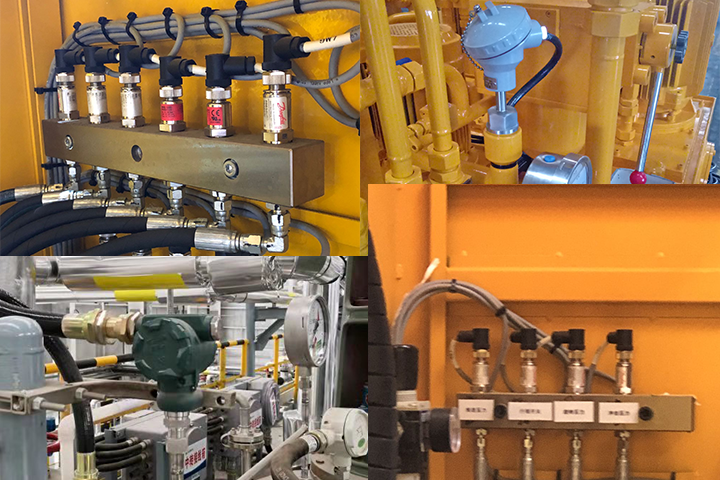

In our continuous journey toward optimization, let’s delve into the benefits of the oem pressure transducer. These devices transform pressure signals into an electrical output, ensuring harmony between physical measurements and digital interpretations. In industries like automotive and aerospace, where safety is paramount, employing top-notch transducers makes a world of difference. The fidelity of these instruments can mean the difference between success and failure, so it’s essential to have trusted technology on your side.

The Rise of Custom Pressure Transducers

Have you considered the importance of tailored solutions? A custom pressure transducer is specifically designed to meet your unique project needs. Rather than relying on generic options that might not fit perfectly—why settle for less? Custom solutions provide enhanced performance and integration capabilities, seamlessly bridging gaps and optimizing processes for specific requirements. As industries push to innovate, personalized sensors prove to be a pivotal ally.

Conclusion and Recommendation

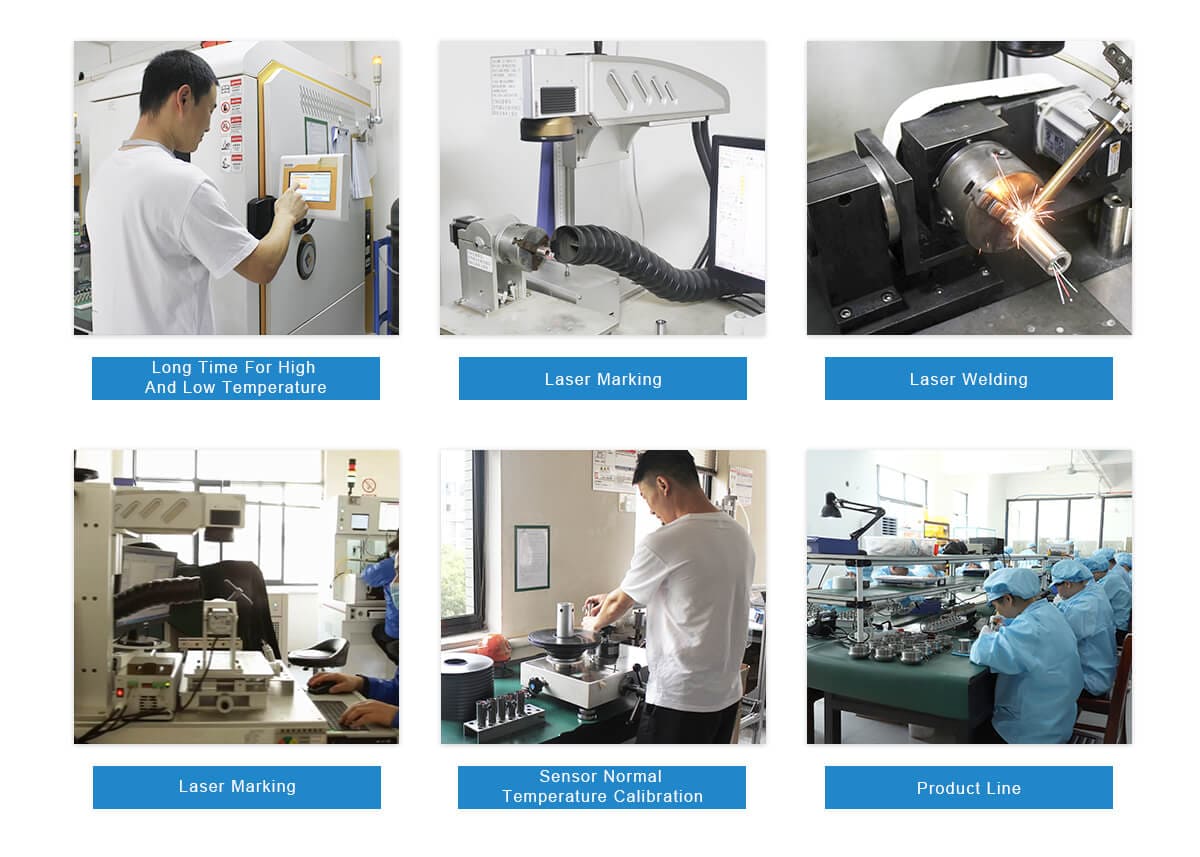

To summarize, understanding and investing in the right pressure sensor solutions can dramatically streamline operations. The best choice comes down to performance metrics and personal needs. Choosing a reputable manufacturer is crucial, and for your pressure sensor requirements, I’d recommend CSSPM Sensor. Known for their supply advantages and cutting-edge technology, they stand ready to elevate your project to new heights.