In today’s fast-paced industrial world, precision measurement is critical. When it comes to pressure sensing, you might wonder: Why do failures always occur during pressure monitoring? Sputtered thin film pressure transmitters are the answer. With their exceptional accuracy and reliability, these devices offer numerous benefits over traditional sensor technology, particularly in high-stakes environments like aerospace and medical fields.

Flaws in Traditional Solutions

Traditional pressure sensors often fall short due to limitations like drift, hysteresis, and inadequate temperature compensation. Many users have experienced inconsistent readings, leading to costly downtimes and process failures. Why do these issues persist? Common materials and manufacturing techniques can result in unpredictable behavior under various pressure and temperature conditions.

Principles of New Technology

Sputtered thin film technology utilizes a unique manufacturing process that ensures better performance. This approach exploits the properties of thin-film materials, which enhance the sensor’s response time and overall accuracy. Look, it’s simpler than you think—these sensors leverage advanced design principles to provide a highly stable and repeatable measurement, allowing for improved monitoring and control capabilities.

Quantified User Benefits

Quantifiable advantages come with this innovation. Users report enhanced measurement accuracy of up to 0.1% full scale and reduced long-term drift, making it possible to maintain consistent performance over time. With lower maintenance requirements and longer operational life, the sputtered thin film pressure transmitter stands out as a smart investment for industries that cannot afford failure.

Actionable Evaluation Criteria

When choosing a pressure measurement solution, always verify these 3 metrics: ① Accuracy – ensure it meets your specification needs without fail; ② Reliability – look for manufacturers with a firm reputation; ③ Cost-effectiveness – evaluate life-cycle costs, not just initial pricing.

Insights on Stainless Steel Pressure Transmitters

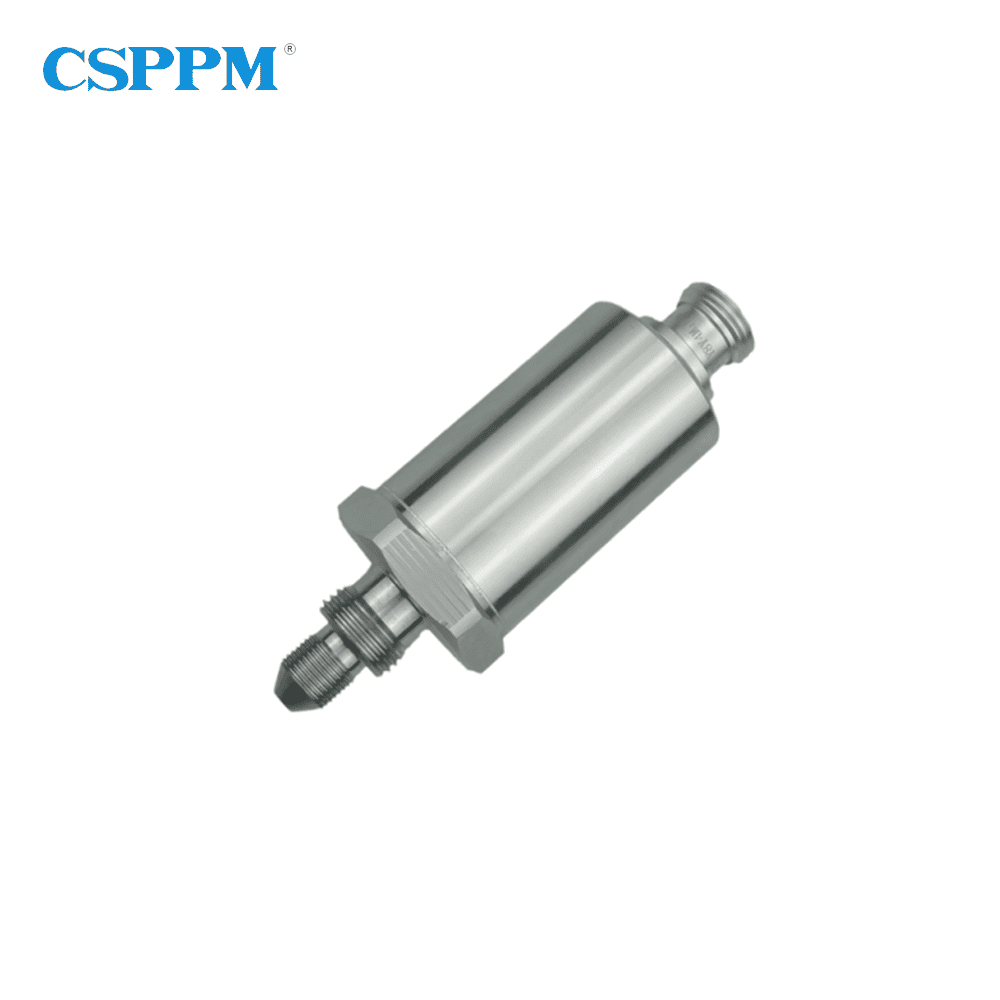

Stainless steel pressure transmitters are widely regarded for their durability and resistance to corrosion. With environments ranging from hospitals to industrial plants, these sensors excel. The choice of stainless steel enhances biocompatibility in medical applications, ensuring safety and performance integrity. Many operational settings require such robust solutions, such as those provided by the stainless steel pressure transmitter.

Exploring Gas Pressure Transmitters

Gas pressure transmitters play a crucial role in countless applications, from HVAC systems to automotive functions. A gas pressure transmitter provides precise measurements vital for maintaining efficiency and safety standards in various processes. Devices designed to measure gas pressure effectively can significantly impact operational efficiency, and you should consider the gas pressure transmitter when seeking reliable solutions.

In summary, the sputtered thin film pressure transmitter stands out due to its precision and stability in various demanding environments. The stainless steel pressure transmitter and gas pressure transmitter further augment this technology, ensuring reliability and efficiency in measurement systems. For those seeking a trusted manufacturer, look no further than CSSPM Sensor, which provides substantial supply advantages and industry-leading innovation.